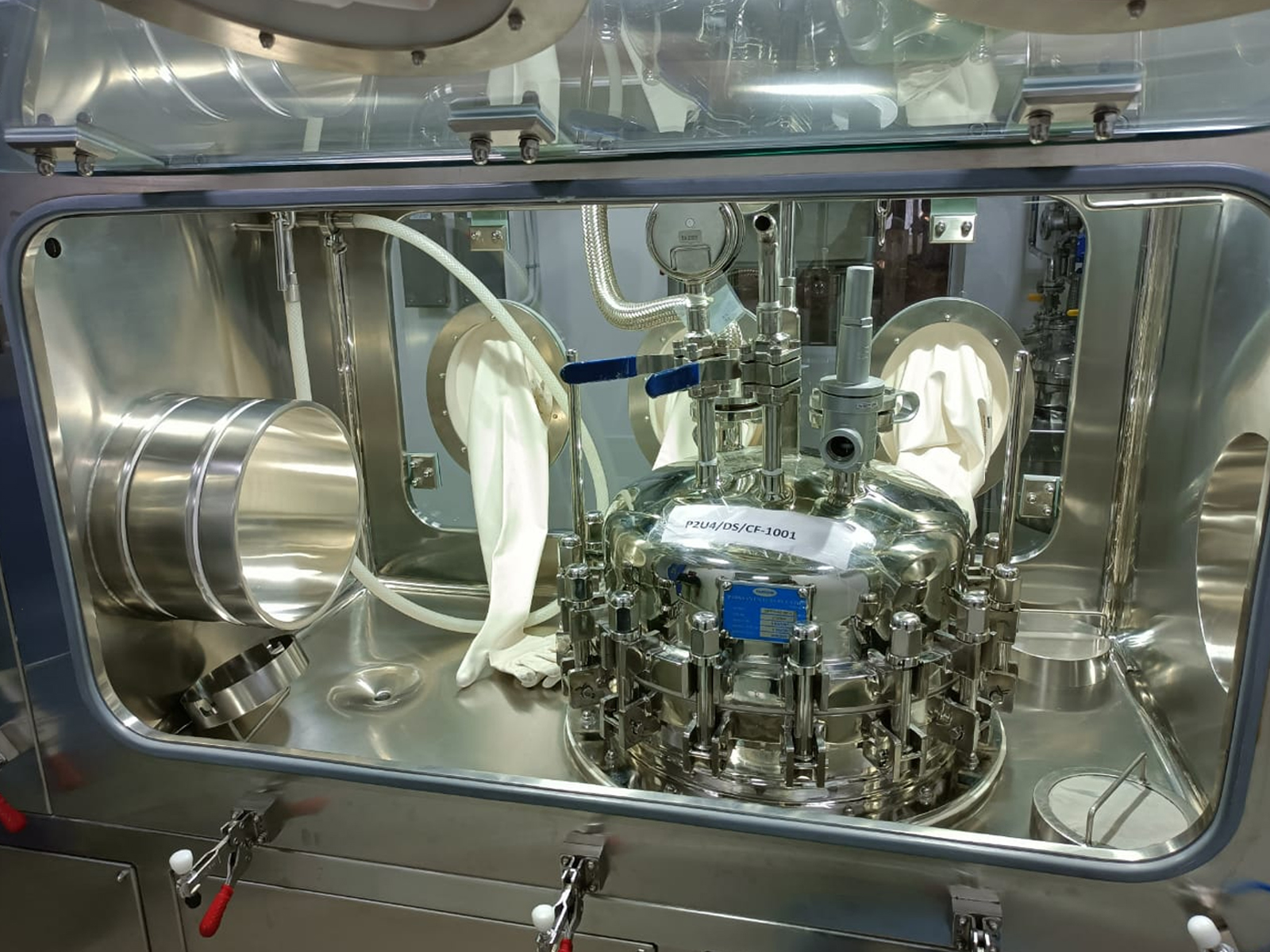

Isolator for Pressure Nutsche Filter

Isolator for Drying and Milling

Active Pharmaceutical Ingredients-(API)

Highly Potent Active Pharmaceutical Ingredients HPAPI facilities are challenging to build, operate and maintain. Each process step although aided by gravity or vacuum is fraught with risks like potency, explosion & product characteristic changes. There is significant use of solvents and chemicals that call for chemical safety levels that in many cases surpass even the most stringent levels.

Product Features

- OEB 4 & 5 Complaint

- Flame proof / Non-Flame Proof construction

- Negative pressure working environment

- N2 Inertiazation system with O2/ Rh level monitoring

- Transfer system suitable to the OEB complaint

- Auto Leak Testing (Optional)

- PLC / HML Operation

- Special Lighting system, for light sensitive product

- Safe change HEPA systems

- EU-14 HEPA for Fresh Air Inlet & Exhaust

- 21CFR Part II Complaint (Optional)

- Safe change glove port design

Product Range

- Sampling, Dispensing Isolator

- Reactor Changing Isolator

- ANFD Discharge Isolator

- Pressure Nutsche Filter Isolator

- Centrifuge Isolator

- Milling and Seiving Isolator

- Micronizer (Air Jet Mill) Isolator

- Spray Drying Isolator

- Packing Isolator

Isolator for Micronizer

Isolator for ANFD

Sampling Isolator

Reactor Charging Isolator

Dispensing Isolator