Active Pharmaceutical Ingredients-(API)

Highly Potent Active Pharmaceutical Ingredients HPAPI facilities are challenging to build, operate and maintain. Each process step although aided by gravity or vacuum is fraught with risks like potency, explosion & product characteristic changes. There is significant use of solvents and chemicals that call for chemical safety levels that in many cases surpass even the most stringent levels.

Product Features

- OEB 4 & 5 Complaint

- Flame proof / Non-Flame Proof construction

- Negative pressure working environment

- N2 Inertiazation system with O2/ Rh level monitoring

- Transfer system suitable to the OEB complaint

- Auto Leak Testing (Optional)

- PLC / HML Operation

- Special Lighting system, for light sensitive product

- Safe change HEPA systems

- EU-14 HEPA for Fresh Air Inlet & Exhaust

- 21CFR Part II Complaint (Optional)

- Safe change glove port design

Product Range

- Sampling, Dispensing Isolator

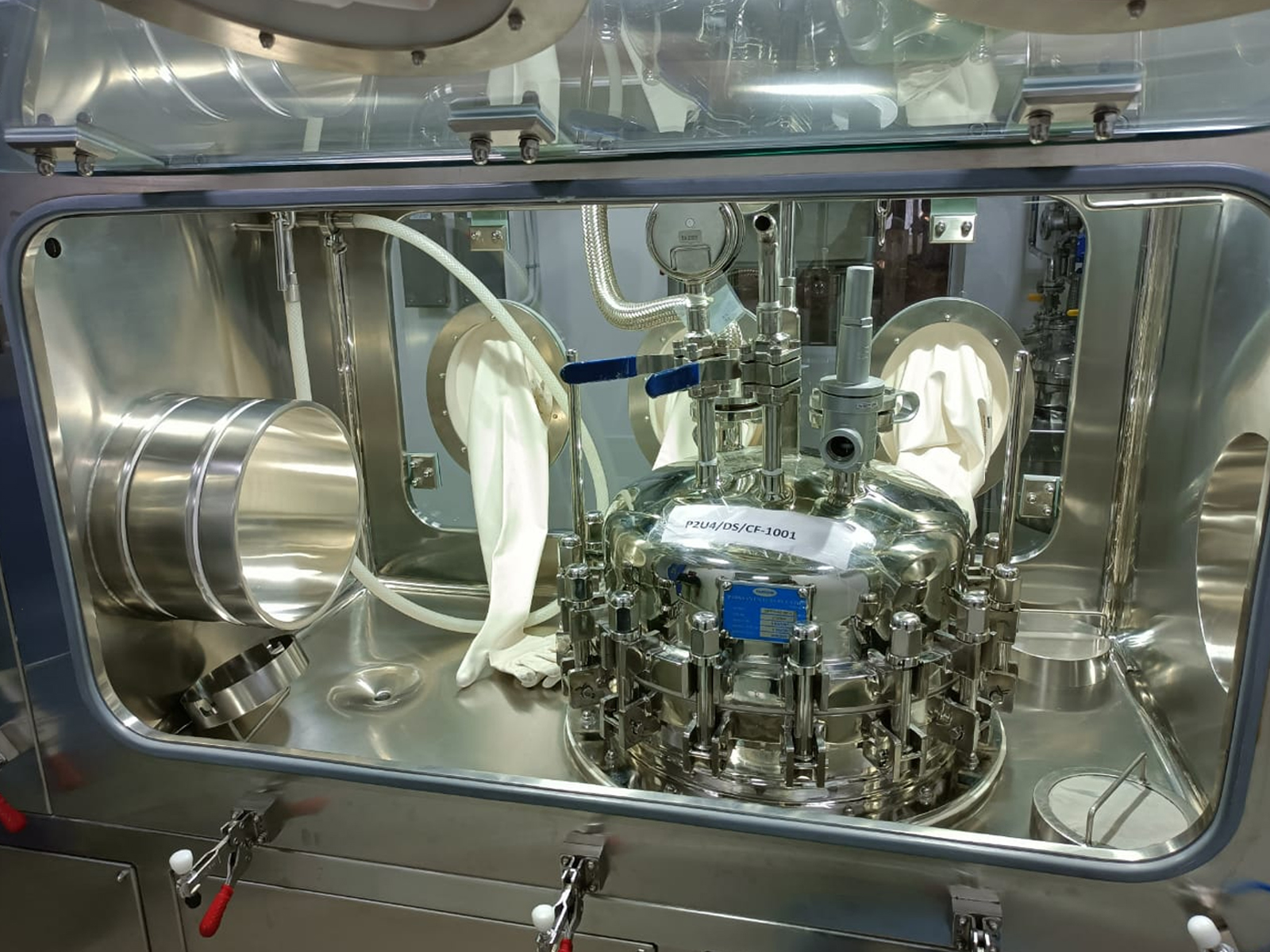

- Reactor Changing Isolator

- ANFD Discharge Isolator

- Pressure Nutsche Filter Isolator

- Centrifuge Isolator

- Milling and Seiving Isolator

- Micronizer (Air Jet Mill) Isolator

- Spray Drying Isolator

- Packing Isolator

Advantage Of Service

Highly Potent Active Pharmaceutical Ingredients HPAPI facilities are challenging to build, operate and maintain. Each process step although aided by gravity or vacuum is fraught with risks like potency, explosion & product characteristic changes. There is significant use of solvents and chemicals that call for chemical safety levels that in many cases surpass even the most stringent levels.