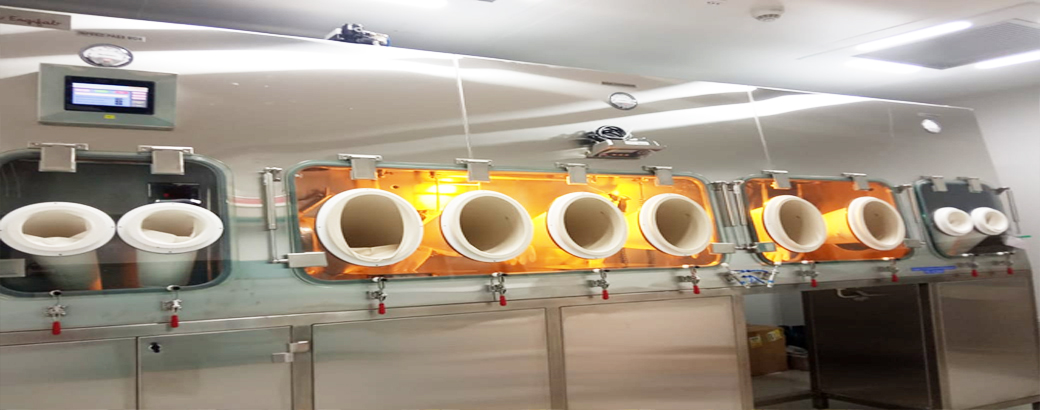

Sampling, Dispensing and Sieving Isolator

Sampling Isolator

Dispensing Isolator

Pack Off Isolator

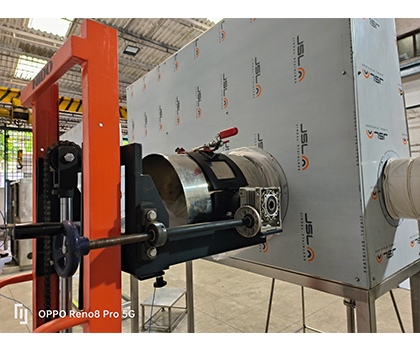

Isolator for HME (Hot Melt Extruder)

Isolator with Drum Docking System

Isolator For Formulation Process

Drying & Co-Mill Isolator

OSD

OSD isolators more as true process solution at such formulator sites varying batch needs rather than just a OEB graded containment module. Collectively with each pharmaceutical user group we have showcased that containment can and must be effortless and process predicated. Granulating, drying, refining, sizing, compressing+ coating, encapsulating, polishing, dedusting no matter the process, containment must be seamless.

Product Features

- OEB 4 & 5 Complaint

- Flame proof / Non-Flame Proof construction

- Negative pressure working environment

- N2 Inertiazation system with O2/ Rh level monitoring

- Transfer system suitable to the OEB complaint

- Auto Leak Testing (Optional)

- PLC / HML Operation

- Special Lighting system, for light sensitive product

- Safe change HEPA systems

- EU-14 HEPA for Fresh Air Inlet & Exhaust

- 21CFR Part II Complaint (Optional)

- Safe change glove port design

Product Range

- Sampling Dispensing Isolator

- Quality Control Isolator

- Isolator For Sifter, HSMG, FBD, Mill, Blending

- Isolator for Capsule filling line

- Isolator for Tablet Press Line

- Isolator for IPQC

- Containment Enclosure for Blister / Bottle Filling Line